- Manufacturer

- Low Voltage Switchgear and MCC

- Capitole 40 (IEC)

- Clink II (IEC)

- Halyester (IEC)

- Rawak

- Medium Voltage

- Xiria

- Power XPert UX

- Chalmit Lighting

- Abtech Junction Box

- BPG (Polyester)

- SX (Stainless / Mild Steel)

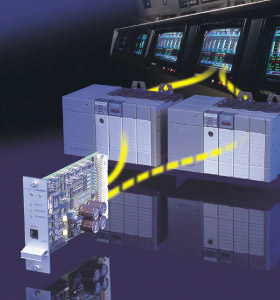

Clink II

Integrated Motor Control System

Clink II is a microprocessor-based automation system with individual control units for each motor and feeder circuit within a Capitole 40 switchboard. It provides plant managers with comprehensive data and opportunities to optimize plant performance, efficiency and productivity.

1. The Starter Control Units execute protection, monitoring and control functions for motors.

2. The Feeder Control Units execute protection monitoring and control functions for feeders.

-

Application

Expand / Close Tab- For each motor in the process

- Protection

- Monitoring

- Control

- Maintenance data

- For each incoming / outgoing feeder

- Measurement

- Control

- Earth Leakage Protection

- Over / Under

- Min / Max

- For switchboard

- Data communication between motor and higher level systems (such as DCS, SCADA, etc.) by application of modern microprocessor technology.

-

Benefits

Expand / Close Tab- Reliability

- Protection independent of communication

- Communication optionally redundant

- Hardware mounted in separate compartment (temperature not exceed 55° C)

- Reliability

- Identical modules for all motor

- All motor data digitally available (what you need is what you get)

- Control and monitoring on different levels:

- DSC level

- SCADA level

- MCC level

- Field level

- Access to other devices due to an open communication network

- Economic

- Faster project engineering, installation and commissioning

- Optimising plant performance, efficiency and productivity

- Preventive maintenance

-

Technical Details

Expand / Close TabSCU / FCU Eurocard size (height 100mm, depth 160mm) SCU / FCU cassette: height 1970mm, depth 2475mm, width 35mm Degree of Protection Mounted in Capitole: IP 42 SCU / FCU: IP 31 CIU: IP 31 Permission Ambient Temperature Operation CIU: 0 -55° C Operation SCU: 0 -55° C Operation FCU: 0 -55° C Storage: 0 -75° C Power Supply Input voltage: 195 - 265 V Frequency: 50/60 Mz System voltage: 24 Vdc Timing Starter Control Unit Response time Motor Control action: 10 ms Response time Motor Protection action: 10 ms Response time Motor Monitoring action: 10 ms Timing Feeder Control Unit Response time digital input: 25 ms Response time digital output: 25 ms Communication to process control system Standard protocol: Modbus / Profitbus / Datahighway / EtherNet / ControlNet / Ethernet Baud rate: Depending on protocol Serial link: Depending on protocol